Adroit has just deployed an innovative data buoy at the Westpac Mussel Farm in the Firth of Thames, now affectionately named ‘Murray’.

Delivering accurate real-time salinity data for mussel harvest compliance.

Shellfish aquaculture is a significant industry in New Zealand, with 600 mussel farms and 300 oyster farms in operation throughout the country.

Mussel farm operators are constantly testing the water quality and taking samples of their product, to see how much microbes are in the mussels, against limits set for harvesting criteria.

And for good reason! When there is heavy rain, run-off comes into the ocean, eventually washing past aquaculture farms. And because mussels are filter feeders – they can filter about 20 liters of water an hour – they suck up anything that’s in the water.

Water salinity is the key measure here. Rain can affect salinity and when salinity drops off, bug counts tend to go higher, which in turn affects the mussels. Therefore, MPI compliance requirements for harvesting set a minimum salinity level. And when it’s reached, farmers need to immediately stop harvesting.

Farmers currently rely on rain gauges to warn them of potential problems, but these might be up to 50 kilometers away from the farm. This can result in unnecessary farm closures when there is highly localised rain near the sensor, but not near the farm.

So, Westpac Mussels was seeking to improve both the speed and the accuracy of the collection of weather information and salinity data, to avoid farms being unnecessarily closed.

Westpac Mussels’ brief had a number of key requirements:

– Realtime, accurate and reliable salinity data, visible via web browser and mobile app

– Data threshold alerting to notify farms when salinity falls below regulated levels

– Ability for MPI to collect data via APIs to meet reporting requirements

– Industrial robust solution capable of withstanding marine conditions

– Lower maintenance required for general antifouling, and sensor cleaning and calibration

Challenges:

There are many challenges for the creation of a data buoy for New Zealand conditions, not least of which is cleaning and maintenance costs of monitoring equipment.

Buoys are constantly wet, exposed to rain and salt water and exposed to algae and bacteria – all of which are problematic for any electronic device.

And inaccurate salinity readings would cause farms to be unnecessarily closed, so reliability of equipment is absolutely important.

Also, with farms being located in often largely unpopulated areas, network connectivity can be limited.

So, the challenge for Adroit was to create a data buoy that would provide in real time, all the data that an aquaculture farm operator needs to know to successfully produce healthy products.

Adroit’s Solution:

Adroit’s philosophy is to work with the world’s leading equipment suppliers and through IoT network connectivity deliver sensor data to Adroits cloud-based IoT Platform. This buoy is a perfect example of this approach delivering a great result.

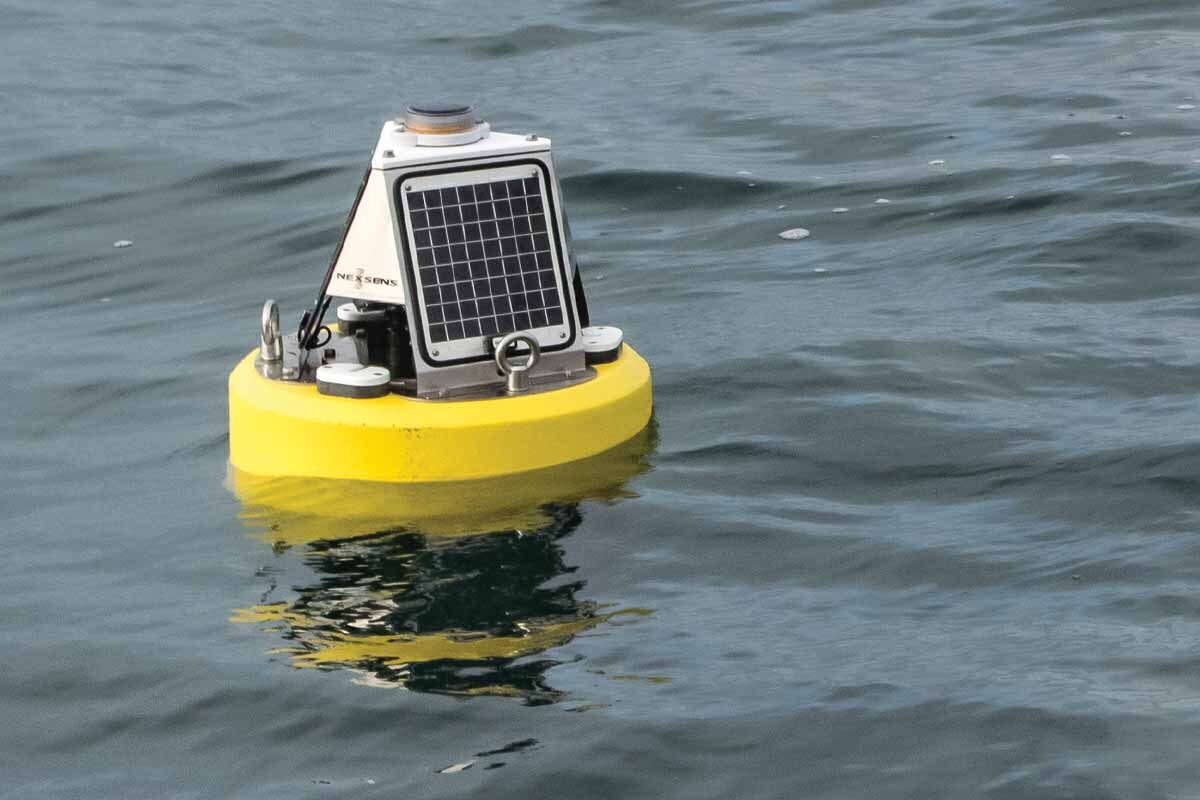

The Adroit Data Buoy monitoring solution provides real-time monitoring of salinity and temperature via a NexSens data buoy, Libelium data logger and In-situ sensor sonde.

In-Situ is a high-quality sonde manufacturer based in the US. The In-situ sonde we’re using is a temperature/conductivity sensor, which can also derive salinity levels. In-Situ sondes are ideal for this kind of marine application because of their extended maintenance cycles of four to six weeks – achieved by using an internal wiper, which cleans the sonde every hour, and also an anti-fouling copper guard that fits on the outside.

This NexSens data buoy is also top of the line – painted in an advanced nanotechnology paint with a range of benefits including anti-fouling, UV protection and self-cleaning. This helps reduce maintenance costs and extends the life cycle of equipment.

Each buoy has a Libelium logger which transfers data via the Spark Cat-M1 network to the Adroit Platform, which can then be viewed via a web browser or mobile app, with customisable dashboards, reporting, and alerting to email.

The Adroit platform is the heart of an IoT system. Data is received into the Adroit platform, where it’s stored and can be visualised on the customisable dashboards, as well as using reporting and alerting tools. Data can also be exported via a CSV file or through the APIs interior existing business applications.

The result is a highly flexible, ongoing solution for future changes and growth of the mussel farm.

Another benefit of the Adroit solution is scalability. Extra data buoys, data loggers and sensors can easily be added when required. This provides highly flexible, ongoing solution for the future changes and growth of the mussel farm.

When we saw the Adroit Data Buoy bobbing in the water in the Firth of Thames, sending out its first stream of data, we knew straight away it needed to be named Murray, a good Kiwi name.

New Zealanders respect good, solid, no-nonsense people and machinery – perhaps it’s the nation’s farming heritage… But we identified straight away that with its robust body, and hardworking components, Murray was going to be reliable and a member of the team for a long time to come.